Conveyor Belts

COMPLETE INSTALLATIONS With all the elements and components needed

Technical assistance and on-site assembly

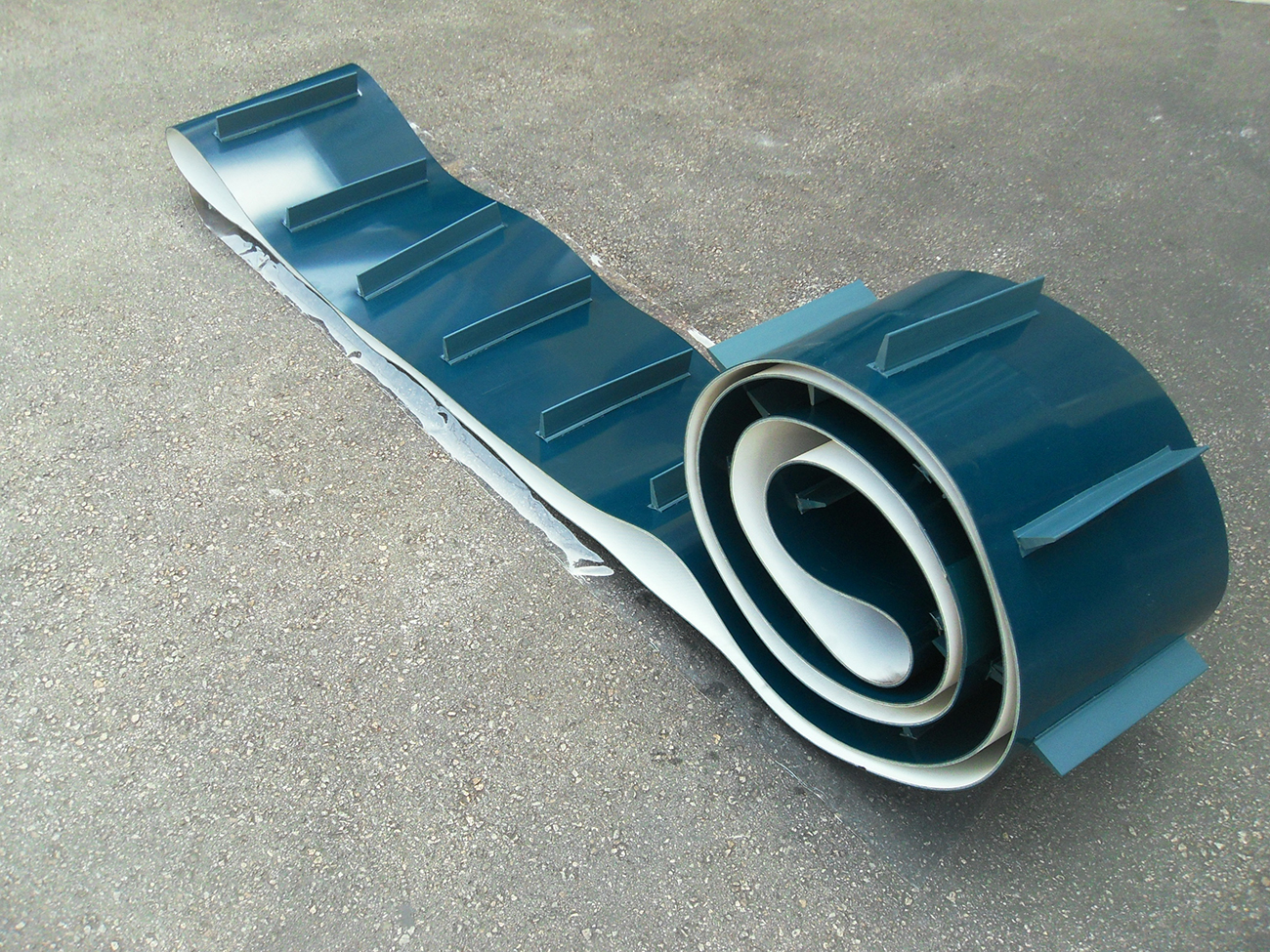

Commercialisation of complete CONVEYOR BELTS or by the metre. We provide you with every required element for self-maintenance: patches, dissolution, union rubber, staples for cold joints, adhesives.

We have a large variety of PVC BELTS of every width and length, for general transportation and specialised in the food industry, and belts that are non-toxic, smooth and engraved with longitudinal or horizontal profiles.

In ![]() INDUSTRIAS DEL CAUCHO S.L.U. has a large variety of conveyor belts: they can be smooth and chevron; anti-heat, for high temperatures; flame-resistant, for installations that need fire safety; oil-proof, for transporting fatty materials; non-toxic, for contact with food.

INDUSTRIAS DEL CAUCHO S.L.U. has a large variety of conveyor belts: they can be smooth and chevron; anti-heat, for high temperatures; flame-resistant, for installations that need fire safety; oil-proof, for transporting fatty materials; non-toxic, for contact with food.

For all kind of industries

High tear resistance

Unbeatable quality price ratio

Strong adherence between textile layers

Rubber edge trim

Low maintenance costs

Manufactured with synthetic fabrics such as polyester-nylon

Low elongation to high strain

TYPES OF RUBBER

NR: Natural |SBR: Styrene-Butadeine |NBR: Nitrile | IIR: Butyl| EPDM: Ethylene Propylene

IDENTIFICATION OF BELTS

| 1200 | EP500 | /4 | 4+2 | Y |

|---|---|---|---|---|

| Bandwidth in millimetres | Tear resistance of the frame | Tarpaulin number | Thickness in mm. of the upper and lower cover | Cover quality |

QUALITY OF THE COVER IN SOLIS BELTS

| Cover quality | DIN Quality Standards | Rubber Base | Temp. Range ºC | Features | Abrasion Loss mm3. |

|---|---|---|---|---|---|

| Abrasion resistant | Y X W |

SBR NR NR/SBR |

-30/100 -40/90 -40/90 |

High resistance to abrasion Excellent resistance, to impacts as well as cuts. It has all DIN X features and is very resistant to hard abrasive materials |

<150 <120 <90 |

| Heat-resistant | T T T |

SBR IIR EPDM |

-20/170 -20/220 -20/400 |

Transport of hot materials Higher heat resistance Resistant up to 400ºC for short periods of time |

|

| Flame-resistant | KS | SBR/NR |

-20/90 -20/90 |

Flame-resistant, for the transport of inflammable or explosive materials. Completely fireproof, fire-resistant and suitable for miner activities |

<200 |

| Oil and grease-resistant | G G |

SBR/NR NBR |

-20/90 -20/120 |

Resistant to hydrocarbons and also to vegetal oils and greases. Resistant to mineral oils and grease |

COMPOSITION AND DESCRIPTION OF BELTS

Our belts are made out of 2 to 6 EP fabrics Polyester (E) for wrap resistance (longitudinal), and Nylon threads (P) for weave resistance (perpendicular). All these parts make up the cover.

As regards to the coating, the upper rubber protects the belt; and the lower one protects the cover.

Their qualities and thickness depend on the type of materials they are transporting. The upper cover is at least 50% thicker than the lower one.

ROLLERS AND COATINGS

Because of their multiple applications, we make the coatings of a big rubber variety resistant to abrasion, oils, greases and general chemical products, in all hardnesses, with and without drawing, without measurements limit.

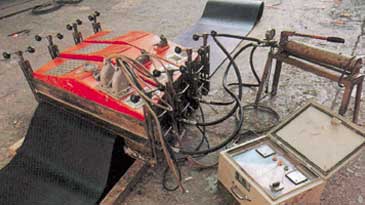

HOT AND COLD JOINT PRODUCTS

Cold joints

Cement + accelerator, primer paint, solvent, patches for reparations, tools.

Hot joints

Vulcanising solution, unvulcanised union rubber, on-the-spot vulcanising press.

Sale of complete “press” equipment for on the spot reparation, and every required element for preventive self-maintenance: solution, patches, union rubber.

Reparation accessories: wire brushes, knives, emery discs for rubber, milling cutters, rubber grater machines.